IMER USA IMER Step Up 120 - 7.5 HP - 3Phase 220v Hi Performance Pump

IMER USA IMER Step Up 120 - 7.5 HP - 3Phase 220v Hi Performance Pump is backordered and will ship as soon as it is back in stock.

Estimated Shipping Widget will be displayed here! (with custom color)

Authorized dealer

Authorized dealer

Your #1 trusted source for IMER USA products.

Shipping info

Shipping info

Most orders are processed and shipped from our USA warehouse within 1 to 3 business days of an order being placed (excluding weekends and holidays).

If, in the case, the item has a different handling and/or shipping estimate, it will be clearly displayed under the Add to cart button.

Returns info

Returns info

Eligible for returns: Yes

Time frame allotted: 30 days from the date of delivery

*Item(s) must be in new and unused condition to be eligible

To learn how to request a return please visit our return & refund policy:

Need assistance? We're happy to help!

Description

Description

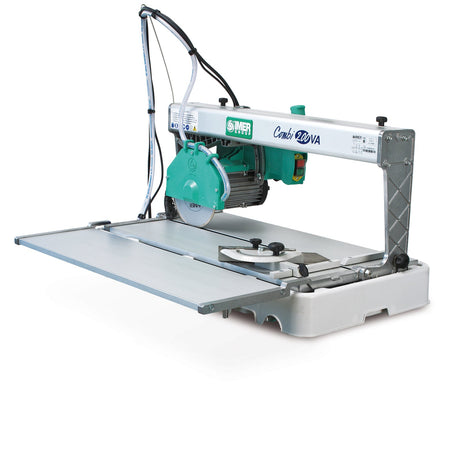

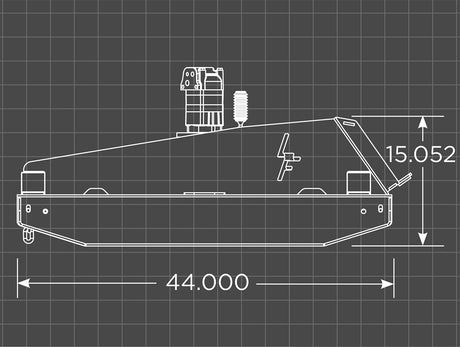

The IMER Step Up 120 - 3Phase 220v Hi Performance Pump - is a more powerful and versatile version of the Step Up 120 Single Phase 220v machine. Though identical in size, the biggest difference is the 220volt three phase Step up 120 has the ability to pump 3/8” aggregate through its IM25L Rotor/Stator using 50mm hose. This allows it to pump and fill block walls or repair forms with high strength 3/8’ aggregate structural grouts.

The compact design of the Step up 120 and its all electric power allow it to operate in space challenged environments often encountered in old buildings being structurally repaired. This makes it the perfect pump for filling overhead repair forms in existing buildings where access and space are an issue.

Look at these features

- 5hp or 7.5 hp 2 Speed 3 PHASE 100% Duty Cycle Electric Motor

- Integrated power panel can run pump, mixer, & air compressor. ( with Optional Mixer and Compressor installed )

- Air switch from spray gun allows spray gun operator control on off flow operation of pump ( With Optional Compressor )

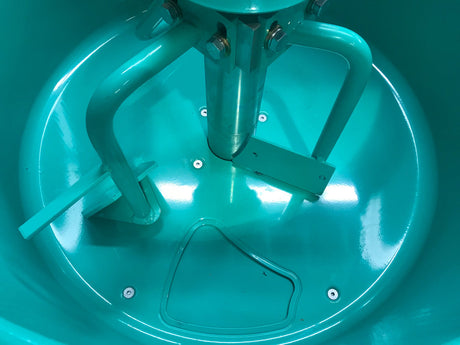

- 3.2 CF MIX 120 vertical shaft mixer drops directly into hopper and is wired for integrated 220v operation (MIXER OPTIONAL)

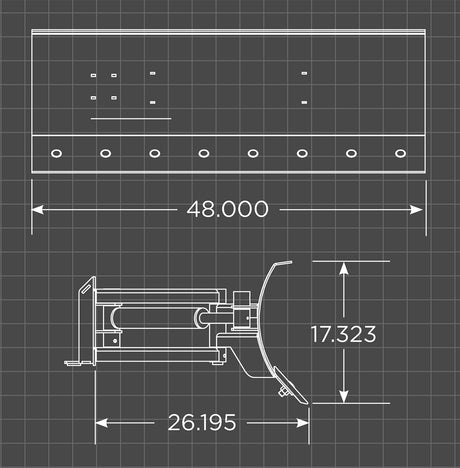

- 33’ - 35mm Material Hose.

- 50mm Male to 35mm Female Cam Lock Reducer

- Torsion bar axle for safe smooth towing

- Pump up to 200ft with 35mm ( 1 3/8” ) diameter hose

- Pumps 3/8” aggregates with 50mm ( 2”) diameter hose.

- Pumps up to 2.75 Cubic yards per hour.

Standard Equipment included with every Step UP 120 - 3 Phase 220v Electric Pump

- 220v 3 Phase Electric control panel with high and low speed options

- IM25L rotor/stator

- 33’ - 35mm Material Hose.

- 50mm Male to 35mm Female Cam Lock Reducer

- Standard Safety Grate

- Tow Kit with Torsion bar Axle

- Accessory tool box

- 133 Ft Super heavy duty 220v power cord

Optional Equipment

- MIX 120 Vertical Shaft Mixer with wired for integrated 220v operation

- 11 CFM 3 Phase Air Compressor

- Spray Gun Kits for conventional or premixed mortars, repair grouts, and Fireproofing. ( no aggregate )

- 35mm Material Hose x 33ft Length with M/F Cam Lock ends

- 100’ of 13mm (9/16) Air Hose with Geka Syle quick couplings

- 5 ft pole gun for spraying fireproofing

- Wired remote (single phase only)

- Vibrating grate (both)

- 2L6 rotor/stator - increases pressure reduces volume (both)

- 60.12 rotor/stator - high volume (3 phase)

Videos

Step-Up 120

Step 120 - Screw pump/Pompa a vite

Step Up 120 Spraying Pre Blended Mortar

Frequently Asked Questions

What is the voltage required?

You will need 220 Volts either single phase or 3 phase depending on the model selected.Can I use Step Up 120 to spray materials?

Yes, the compressor, hoses and gun kit is included. The gun kit includes 50' or air and material hose, gun and tips.What kind of materials can I use?

The Step Up 120 is a very versatile pump. You can use it for mortar,stucco,grout,fireproofing,self-leveling underlayment,slab-jackting etc.How much hose can I use with this?

It depends on the application. Some materials such as SLU (self-leveling underlayment) can travel a far distance. It was tested with 300' of hose with no issues horizontally. Other applications such as pumping upwards with mortar might limit you to 120' vertically. The 3 phase model has more power to pump further. The more fluid the grout and the more cement content the further it will travel. A 3,500 PSI grout will not travel as far as a 5,000 PSI grout. Pumping upwards reduces the pumping distance by more than 60%. Different rotors and stators can increase pumping distance but usually at the expense of flow. Consider the pot life of the product being pumped or sprayed. If you have a short pot life then adding more hose is counter productive as it could start to set while travelling in the hose.Can I start and stop the pump remotely?

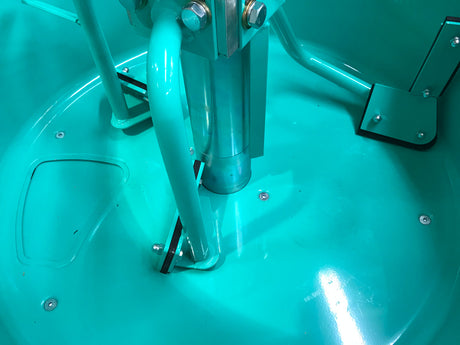

Yes, the included wired remote when plugged in will override the start and stop of the pump when the switch is turned to "on". Reverse and stop will still function from the panel. If using with the compressor and a gun kit, then the wired remote is not needed. Opening and closing the air valve on the gun will trigger the pressure switch on the compressor to start and stop the compressor and the pump as a system. In either case, both the compressor or wired remote are enabled when the pump switch is turned to "forward". A flashing number and the word "stop" will display on the panel. This indicates the speed of the pump and the pump is on standby waiting for the operator to open the gun valve or press the button on the switch.How do I tune-up the adjustable stator?

IMER USA uses adjustable stators which will give you longer working life than a non-adjustable stator. As abrasive materials such as grout and mortar which contain sand travel through the rotor and stator some wear will occur. The bolts on the stator squeeze the rubber inside the stator to accommodate for this wear so that it will maintain the proper pressure.What does the inverter do?

The inverter is what makes this pump function well on 220V, single phase. What the inverter does is electronically recreate the sine wave of the electricity coming in via software. This also allows the frequency to be raised or lowered which results in speeding up or slowing down the pump, indicated on the control panel. Because the inverter reconfigures the voltage, amperage and frequency of the current to the motor it can work in parameters in which most motors would burn up. You can use the Step Up 120 from 185-250 Volts. The pump will shut down with an error code if the voltage is too low. It will shut down immediately if the voltage is too high which could burn up the inverter quickly. The blue light will flash on and off quickly If voltage is too high. The inverter program also allows for the start of the motor to wind up slowly greatly reducing the initial amperage spike. Traditional motors usually require 2.5x the working amperage for an instant to get started. The inverter will give an error code on the display if it encounters trouble instead of tripping a circuit breaker leaving you guessing what the issue may be. The inverter error codes can tell you if the motor or inverter too hot, material not suitable or motor struggling, voltage too low, grill removed or emergency stop button pushed in. It can even tell you if there is an air leak in the compressor which keeps cycling on and off. The inverter is the cornerstone of the IMER Pumps which run on single phase. Single phase pumps have been plagued in the past for being too wimpy to be usable. The inverter changes all that.Can I pump continuously with this?

The Step Up 120's use a 100% duty cycle motor than can run continuously 24/7. The inverter will shut it down if it ever exceeds the working temps on the single phase unit.How long will a rotor and stator last?

Depends on the material being used. If using a silky smooth material such as straight portland cement then thousands and thousands of bags. If using a product that is very abrasive such as Euchoshot or product with silica fume then maybe just a few hundred. Routine maintenance should be performed at the end of each work day to ensure that the rotor / stator are well calibrated. Tip: To calibrate the stator, fill the hopper with water, set the speed to 50Hz, attach the material hose to the end of the pressure gauge, Kink the hose as you would a water hose and turn on the pump. The pressure gauge should read 120-140 PSI. If it does not then tighten the 3 bolts on the adjustable stator evenly. Check again. Continue this procedure until you achieve this pressure. If you cannot achieve this pressure then you might need to replace the rotor and stator.What size aggregate can I pump?

The Step UP 120's come with an IM25L rotor/stator which can handle up to 3/8" aggregate. The single phase unit is limited to 20-25% aggregate depending on the type of stone. The 3 phase model can handle up to 40% of 3/8" aggregate. To use with 3/8" aggregate you will need to multiply 3/8" aggregate X 5 which equals 1-7/8". Our 50mm hose is roughly 2" inside diameter. Using smaller hose will result in clogs.What does changing the rotor/stator type do?

The rotor and stator is sort of like the transmission in a vehicle. The different ratios can increase or decrease flow usually at the expense of higher or lower pressure. A higher flow rate usually means that the material entering the stator is pushed out quickly. For example, our green stator only needs 3 revolutions for the material to enter and then exit from top to bottom. A stator with 5 lobes would need 5 turns to exit from top to bottom. Thus, the 3 lobe stator is almost double the speed of the 5 lobe. The more lobes the higher the working pressure. Think of a screw or bolt. A bolt with tighter threads will be easier to turn but will require more turns to clamp down onto a nut. Less force is needed on a wrench to turn it but will require a lot more turns.What is the maximum pressure that I can pump with?

Depending on the stator but our IM25L stator can achieve up to 450 PSI.How many 50 lb. bags can it pump per hour?

Typically, the Step Up 120 with the standard stator can pump 2,50 lb bag per minute or 120 bags per hour. The 3 phase model can handle 3, 50 lb bags per minute or 180 bags per hour. Different materials may have different yield per bag depending on the density and water volume. A bag of non-shrink grout is about. 45 CF per bag. A bag of fireproofing material could yield 4+ CF per 50 lb. bag. Adding more hose or pumping higher can reduce the flow rate causing a higher working pressure and friction in the line.What mixer do you suggest to feed it?

The Step Up 120 pumps come with a vertical shaft mixer built in. Mix it and open the hatch to allow the mix to flow down into the hopper.Do I need to prime the hose?

Yes, If using a material such as grout, mortar, stucco or any material that has sand in it. The lower the compressive strenght or cement content the more critical it is to prime the hose. To prime the hose with cement based product you will need to mix up about 1/3 of a 5 gallon buck with portland cement to a consistency of pancake batter. Pour the mixture into the hopper and pump it through the hose. You don't need to see the slurry. This will lubricate and line the inside of the hose with cement. Failure to follow these steps whenever the hose is clean will most likely result in a clog of the hose. Certain products do not need the slurry such as fireproofing, most SLU's and acrylics or epoxies.What is the vibrating screen used for?

The screen is there to filter out any large stones that might make their way into the pump. This is especially a nuisance when spraying material as a stone can clog up the tip of the gun causing a shut down of the pump. The screen is usually not needed with bagged material but is recommended for stucco's using bulk sand.Documentation

Specifications

Specifications

IMER Step Up 120 - 7.5 HP - 3Phase 220v Hi Performance Pump

| Specifications | |

|---|---|

| Step Up 120 Pump with Mixer | 220v Single Phase |

| Pump motor power rate | 3hp |

| Mixer motor power rate | 2hp |

| Electric compressor | 1hp / 9cfm |

| Max aggregate size with IM 25L rotor/stator | 1/4” |

| Maximum material flow rate (cubic yards) | 2 / hour |

| Horizontal pumping distance* | 130 feet |

| Vertical pumping distance | 50 feet |

| Pump hopper capacity | 4.25 cubic feet |

| Mixer drum batch output | 3.2 cubic feet |

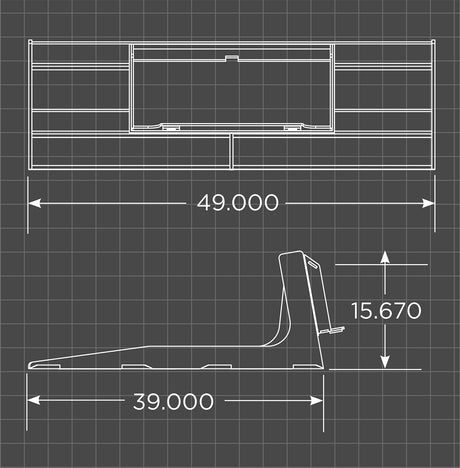

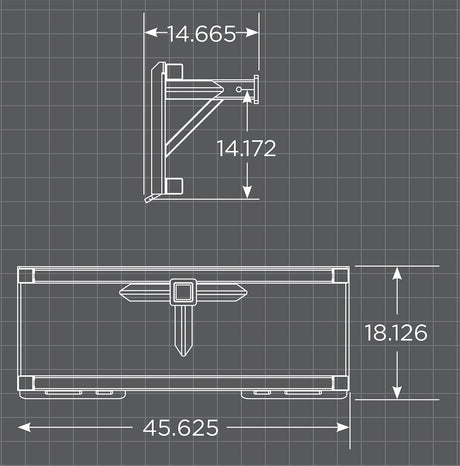

| Dimensions W x L x H (inches) | 32 / 80 / 50 |

| Weight | 888lbs |

| 220v Three Phase | |

|---|---|

| Pump motor power rate | 5hp low/7.5hp high |

| Mixer motor power rate | 1.5 hp |

| Electric compressor | 3hp / 11cfm |

| Max aggregate size with IM 25L rotor/stator | 3/8" |

| Maximum material flow rate (cubic yards) | 1.35/2.75 - hour |

| Horizontal pumping distance* | 200 feet |

| Vertical pumping distance | 100 feet |

| Pump hopper capacity | 4.25 cubic feet |

| Mixer drum batch output | 3.2 cubic feet |

| Dimensions W x L x H (inches) | 32 / 80 / 50 |

| Weight | 900lbs |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.

Call us

Call us